Copyright © 2017 Zhejiang Hexing Maching Manufacturing Co., Ltd All Rights Reserved. 浙ICP备17039855号 Powered by www.300.cn

Mobile browsing

Contact Us

Add:Huzhou, Zhejiang Province, Changxing Lu Shan Industrial Park

Tel:13857249708 +86-572-6696166

Contact: Manager Guo

Fax:+86-572-6696033

DU series rubber belt vacuum filter

DU series rubber belt vacuum filter

Operating principle

The rubber belt type vacuum filter uses the filter cloth as the filter medium and adopts the whole ring rubber tape as the vacuum chamber. The circular rubber belt is driven by a transmission to run in a straight line, and the solid liquid of the slurry is separated by a linear moving water seal system. The solid is carried on the filter strip and removed by a scraper. The liquid is received by the automatic discharge tank and discharged through the water seal or switch device. Filter cloth is continuously cleaned by high pressure washing device to obtain regeneration. Continuous operation, continuous filtration, material from feed, dehydration, slag removal to filter cloth cleaning, can be carried out continuously. The equipment can realize continuous automatic operation, complete feed, dehydration, slag removal, filtration automatic discharge, filter slag washing upstream, filter cloth cleaning and correction and other functions.。

Features of DU type devices

(1)Modular design, multi-section combination for transportation, disassembly, installation, maintenance and maintenance.

(2)The rubber belt is vulcanized at one time, the tensile strength is large, the inner and outer surface quality is good, and the service life is long.

(4)Filter correction adopts double airbag cylinder serpentine correction, automatically adjusting the offset of filter cloth.

(5)The tension of the filter cloth adopts the gravity slider tension limiting device to automatically adjust the looseness of the filter cloth.

(6)Accompanied anti-wrinkle exhibition cloth spiral roll, prolong the service life of filter cloth.

(7)The running speed of 1-15 times can be adjusted, and the best running speed can be selected according to the material parameters.

(8)The integral non-metallic vacuum slide reduces the wear of the sealing belt and extends the service life of the associated parts.

(9)Filter cloth cleaning by rotating nozzle, continuous online cleaning to prevent clogging.

(10)The control box can achieve remote and field dual control, simple and convenient operation, with monitoring and alarm functions(user choice).

(11)According to different materials, it can achieve downstream, countercurrent washing and filter cake reverse washing, reduce the amount of water washing and reduce environmental protection pressure.

Advantages of DU type equipment

1、Wide range of adaptable materials

It is especially suitable for filtration and washing of various kinds of materials with large solid particles and fast settlement.

2、Filter cloth online cleaning regeneration excellent

Always run continuously without blockage, and always maintain a constant filtering ability.

3、Large range of speed adjustments

The best filtering effect can be obtained by adjusting the filter speed and the filter cake thickness.

4、Filter slag washing to meet different process requirements

According to the material characteristics, set up multiple countercurrent washing sections to meet different process requirements, reduce the process route and reduce equipment investment.

5、Operation of linear seal with high vacuum utilization

Movement straight line water seal, seal air entry, achieve maximum vacuum utilization.

6、Stable and reliable discharge method, strong environmental protection and safety

According to the plant conditions, the liquid discharge mode can be flexibly changed to meet the closed water seal discharge and the switched zero-position difference discharge.

7、Automatically running continuously, reducing labor intensity

Self-feed to discharge slag, discharge fluid, filter cloth correction, filter cloth tensioning, filter cloth cleaning are all automatic operation

8、Low operating and maintenance costs

The vulnerable parts are less, the process scheme is superior, and the operation and maintenance costs are low.

DU Type Selection Guide

1、 Select equipment type according to solid liquid ratio, feed quantity, solid particle size, viscosity, solid specific gravity;

2、 Select material, solid particle size, material temperature and filter medium according to PH value of material;

3、 Materials containing volatile gases or vapors can be selected from semi-sealed or fully sealed models;

4、 Washing material should choose vacuum room length > 10m model, special washing, choose leaching model;

5、 Performance materials not used in the same industry should be tested for selection;

6、 Preference to choose the effective width of the national standard model.

Filter diagram

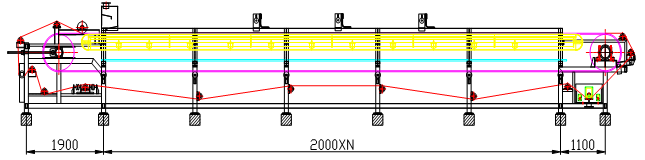

Layout plan of the facade

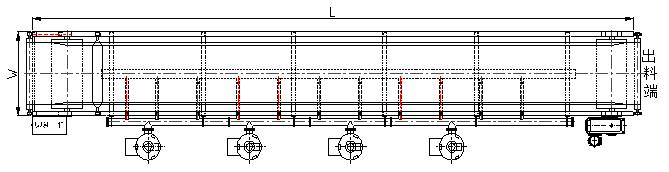

Layout plan

DU application range

|

Chemical group |

Minerals |

Fertilizer class |

Food |

Environmental protection |

|

4A Zeolite |

Coal mud |

Phosphate gypsum |

acetic acid |

desulphurization gypsum |

|

Aluminum fluoride |

Copper concentrate |

Calcium bicarbonate |

Starch derivatives |

Desell fly ash |

|

aluminum oxide |

Gold sediment |

Barium carbonate |

Calcium citrate |

River sludge |

|

Cobalt carbonate |

Ilmenite |

calcium carbonate |

Calcium oxalate |

Oilfield sludge |

|

Aluminum hydroxide |

Quartz sand |

Calcium sulfate |

glutamate |

Construction sludge |

|

Red Mud |

Manganese carbonate |

Calcium nitrate |

sucrose |

Urban sludge |

|

Zirconium chloride |

phosphorous salt |

Nitrophosphorous mud |

citric acid |

Factory sludge |

|

Aluminum |

Red mud |

|

lactic acid |

Plaster repulp |

|

Silicon slag |

Gold concentrate |

|

maltose |

Iron tailings |

|

zinc oxide |

Iron concentrate |

|

Aspartame |

Copper tailings |

|

氢氧化镍 |

铁尾矿 |

|

|

锰尾矿 |

|

碳酸锆 |

铜尾矿 |

|

|

铝尾矿 |

|

硫酸锆 |

钾盐 |

|

|

锌尾矿 |

|

草酸钴 |

五氧化二钒 |

|

|

硫尾矿 |

|

活性炭 |

镍矿 |

|

|

钾尾矿 |

|

磷酸铝 |

|

|

|

钒尾矿 |

|

硫酸铝 |

|

|

|

|

|

氨基酸 |

|

|

|

|

|

钡盐 |

|

|

|

|

|

硼酸盐 |

|

|

|

|

|

硼酸 |

|

|

|

|

|

溴盐 |

|

|

|

|

|

锌盐 |

|

|

|

|

|

催化剂 |

|

|

|

|

|

染料中间体 |

|

|

|

|

|

工业洗涤剂 |

|

|

|

|

|

氧化铁 |

|

|

|

|

|

氧化铝 |

|

|

|

|

|

碳酸镁 |

|

|

|

|

|

氢氧化镁 |

|

|

|

|

|

镍盐 |

|

|

|

|

|

磷酸 |

|

|

|

|

|

增塑剂 |

|

|

|

|

|

气化灰渣水 |

|

|

|

|

|

煤灰水 |

|

|

|

|

DU系列橡胶带式真空过滤机选型技术参数表

|

系列 |

过滤面积(m²) |

滤带有效宽(mm) |

过滤有效长(mm) |

整机总长L(mm) |

机身宽度W(mm) |

机身高度H(mm) |

重量(t) |

真空耗量(m³/min) |

|

500 |

3 |

500 |

6000 |

10000 |

1150 |

1800 |

6 |

12-15 |

|

4 |

8000 |

12000 |

6.5 |

16-18 |

||||

|

5 |

10000 |

14000 |

7 |

20-22 |

||||

|

6 |

12000 |

16000 |

7.6 |

24-26 |

||||

|

630 |

4 |

630 |

6500 |

10000 |

1250 |

1800 |

6.3 |

16-18 |

|

5 |

8500 |

12000 |

6.8 |

20-22 |

||||

|

6 |

10000 |

14000 |

7.5 |

24-26 |

||||

|

7 |

12000 |

16000 |

8.2 |

26-28 |

||||

|

1000 |

6 |

1000 |

6000 |

10000 |

1650 |

2050 |

8 |

24-26 |

|

8 |

8000 |

12000 |

8.8 |

28-30 |

||||

|

10 |

10000 |

14000 |

9.6 |

32-35 |

||||

|

12 |

12000 |

16000 |

10.4 |

36-38 |

||||

|

14 |

14000 |

18000 |

11.1 |

38-40 |

||||

|

1300 |

10 |

1300 |

8000 |

12000 |

2000 |

2050 |

9.8 |

30-32 |

|

13 |

10000 |

14000 |

10.8 |

32-35 |

||||

|

16 |

12300 |

16000 |

11.5 |

36-39 |

||||

|

18 |

14000 |

18000 |

13.2 |

41-45 |

||||

|

21 |

16300 |

20000 |

15.1 |

46-50 |

||||

|

1800 |

14 |

1800 |

8000 |

12000 |

2450 |

2200 |

10.9 |

33-36 |

|

18 |

10000 |

14000 |

12.8 |

41-45 |

||||

|

22 |

12300 |

16000 |

15.3 |

46-50 |

||||

|

26 |

14500 |

18000 |

18.8 |

55-60 |

||||

|

30 |

16500 |

20000 |

22.5 |

60-75 |

||||

|

32 |

18000 |

22000 |

23.8 |

64-80 |

||||

|

36 |

20000 |

24000 |

24.7 |

72-90 |

||||

|

2000 |

20 |

2000 |

10000 |

14000 |

2650 |

2200 |

14.2 |

40-50 |

|

24 |

12000 |

16000 |

17.8 |

48-60 |

||||

|

28 |

14000 |

18000 |

20.2 |

56-70 |

||||

|

32 |

16000 |

20000 |

23.6 |

64-80 |

||||

|

36 |

18000 |

22000 |

27.5 |

72-90 |

||||

|

40 |

20000 |

24000 |

31.2 |

80-100 |

||||

|

2500 |

20 |

2500 |

8000 |

12200 |

3150 |

2300 |

14.8 |

40-50 |

|

25 |

10000 |

14200 |

18.6 |

50-62 |

||||

|

30 |

12000 |

16200 |

22.2 |

60-75 |

||||

|

35 |

14000 |

18200 |

26 |

70-88 |

||||

|

40 |

16000 |

20200 |

29.8 |

80-100 |

||||

|

45 |

18000 |

22200 |

32.9 |

90-115 |

||||

|

50 |

20000 |

24200 |

36.8 |

100-125 |

||||

|

3000 |

36 |

|

12000 |

16400 |

3650 |

2400 |

27.5 |

72-90 |

|

42 |

14000 |

18400 |

32.5 |

84-105 |

||||

|

48 |

16000 |

20400 |

38.5 |

96-120 |

||||

|

54 |

18000 |

22400 |

44.3 |

108-135 |

||||

|

60 |

20000 |

24400 |

49.6 |

120-150 |

||||

|

66 |

22000 |

26400 |

54.8 |

132-165 |

||||

|

72 |

24000 |

28400 |

60 |

144-180 |

||||

|

3200 |

51 |

3200 |

16000 |

20200 |

3850 |

2500 |

35.5 |

102-128 |

|

59 |

18500 |

22800 |

40.2 |

118-180 |

||||

|

64 |

20000 |

24200 |

46.3 |

128-160 |

||||

|

72 |

22500 |

26800 |

52.5 |

144-200 |

||||

|

78 |

24500 |

28800 |

59.6 |

156-220 |

||||

|

3800 |

76 |

3800 |

20000 |

24200 |

4400 |

2800 |

|

152-220 |

|

85 |

22500 |

26800 |

63.6 |

170-240 |

||||

|

91 |

24500 |

28800 |

66.5 |

188-255 |

||||

|

100 |

26500 |

30800 |

69.8 |

200-280 |

||||

|

4000 |

80 |

4000 |

20000 |

25000 |

4800 |

2800 |

61.2 |

160-240 |

|

88 |

22000 |

27000 |

65.6 |

176-255 |

||||

|

96 |

24000 |

29000 |

68.6 |

192-288 |

||||

|

104 |

26000 |

31000 |

73.8 |

208-310 |

||||

|

112 |

28000 |

33000 |

79.6 |

225-336 |

||||

|

120 |

30000 |

35000 |

88.2 |

240-360 |

||||

|

4500 |

90 |

4500 |

20000 |

25000 |

5300 |

3000 |

66.6 |

180-270 |

|

99 |

22000 |

27000 |

69.8 |

200-300 |

||||

|

108 |

24000 |

29000 |

86.8 |

220-330 |

||||

|

117 |

26000 |

31000 |

82.2 |

240-360 |

||||

|

126 |

28000 |

33000 |

91.8 |

260-390 |

||||

|

135 |

30000 |

35000 |

99. |

280-420 |

||||

|

4800 |

168 |

4800 |

35000 |

46000 |

5600 |

3000 |

166.2 |

380-500 |